How to Select the Right Laser Cutting Machine

November 15, 2023

Laser Cutting Industry in Pakistan

November 30, 2023The Future of Mechanical Parts Production with Laser Cutting

In the realm of manufacturing and mechanical engineering, precision is paramount. Mechanical parts that power our everyday lives, from the engines in our cars to the machines in our factories, rely on precise engineering and manufacturing. In this pursuit of precision, laser cutting has emerged as a game-changing technology, transforming the way mechanical parts are designed and produced. This article delves into the world of laser cutting for mechanical parts, exploring its technology, applications, benefits, and its role in shaping the future of manufacturing.

-

The Evolution of Laser Cutting

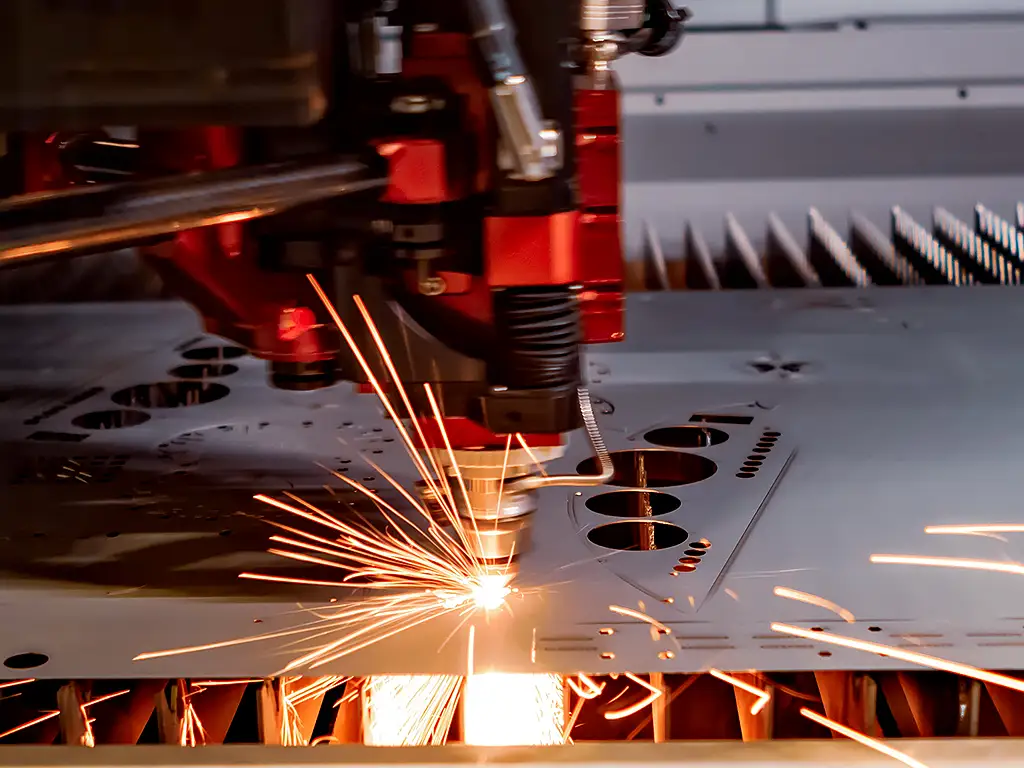

Laser cutting is a technology that has evolved significantly over the years, and it continues to advance at a rapid pace. Initially developed for industrial applications in the mid-20th century, it has become an indispensable tool in the manufacturing industry. Laser cutting relies on the use of a high-powered laser to cut, engrave, or mark materials with precision. The laser beam is focused on the material’s surface, generating intense heat that melts, vaporizes, or blows away the excess material, leaving behind an accurately cut piece.

-

Advantages of Laser Cutting for Mechanical Parts

Laser cutting offers a plethora of advantages that make it an ideal choice for producing mechanical parts:

2.1. Precision and Accuracy: Laser cutting provides exceptional accuracy, ensuring that even the most intricate designs are executed with perfection. This precision is crucial for mechanical parts, where the slightest deviation can lead to malfunction or inefficiency.

2.2. Versatility: Laser cutting can be applied to a wide range of materials, including metals, plastics, ceramics, and composites, making it adaptable to diverse mechanical part requirements.

2.3. Speed and Efficiency: The laser cutting process is remarkably fast, reducing production time and costs. This efficiency is especially valuable for high-volume manufacturing.

2.4. Minimal Material Waste: Laser cutting is a non-contact process, which means there is minimal wear and tear on cutting tools, and the material waste is significantly reduced.

2.5. Complex Designs: Laser cutting allows for the creation of intricate and complex designs that might be challenging or impossible to achieve with traditional machining methods.

- Applications of Laser Cutting in Mechanical Parts

Laser cutting has found extensive applications in the production of mechanical parts across various industries:

3.1. Automotive Industry: Laser-cut parts are prevalent in automobiles, from engine components to body panels. The precision and speed of laser cutting enhance the quality and efficiency of automotive manufacturing.

3.2. Aerospace Industry: Mechanical parts in aircraft and spacecraft demand the utmost precision and reliability. Laser cutting is instrumental in crafting lightweight and durable components for these applications.

3.3. Medical Devices: The medical industry relies on laser-cut parts for surgical instruments, implants, and diagnostic equipment, where precision and cleanliness are critical.

3.4. Electronics: Laser cutting is used to fabricate intricate parts for electronics, such as microchips, PCBs, and connectors, contributing to the miniaturization and improved functionality of electronic devices.

3.5. Industrial Machinery: Mechanical parts in heavy machinery and industrial equipment benefit from the strength and precision of laser-cut components, ensuring durability and longevity.

- The Role of CAD/CAM in Laser Cutting

Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software play a pivotal role in laser cutting for mechanical parts. CAD software is used to create detailed digital designs of the components. These designs are then converted into machine-readable instructions by CAM software, which guides the laser cutting machine in producing the desired part with precision. The integration of CAD/CAM systems with laser cutting technology has revolutionized the manufacturing process, allowing for rapid prototyping and customization of mechanical parts.

-

Quality Control and Inspection

Maintaining the highest standards of quality is essential in mechanical part production. Laser cutting is often paired with sophisticated quality control and inspection systems to ensure that each part meets the required specifications. Automated inspection methods, such as laser scanning and coordinate measuring machines (CMM), are used to verify the accuracy and quality of laser-cut parts.

- Future Trends and Innovations

Laser cutting continues to evolve, and several exciting trends are shaping the future of this technology in mechanical part production:

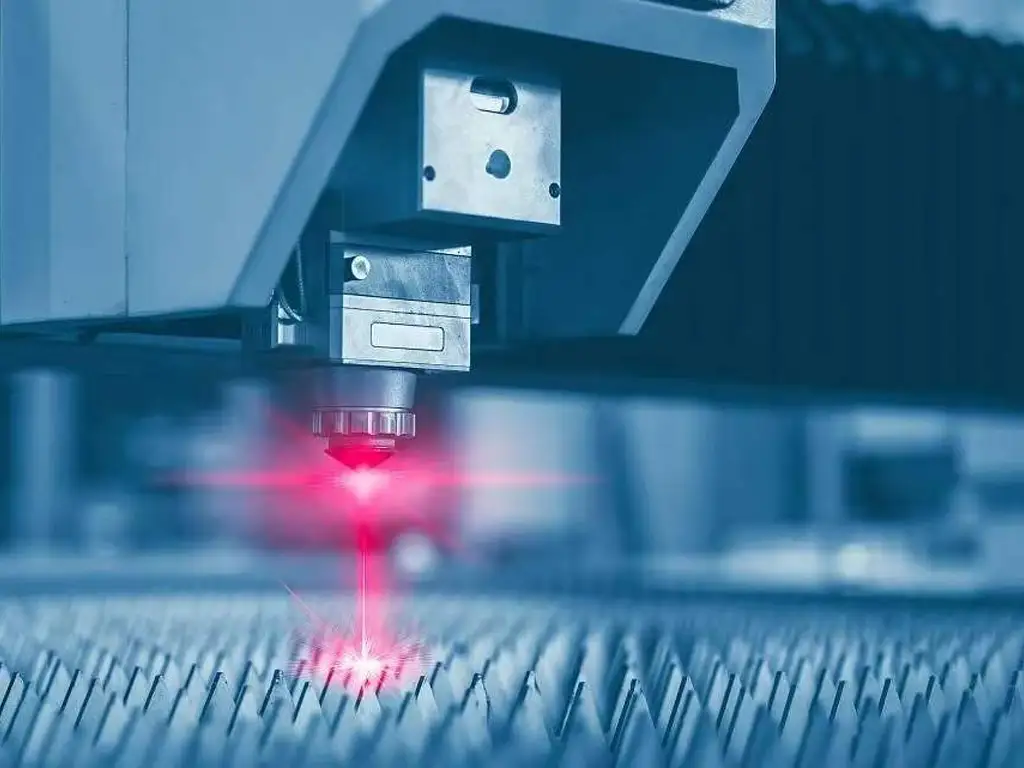

6.1. Fiber Laser Technology: Fiber lasers offer increased energy efficiency and precision, making them the preferred choice for many industries. Their enhanced cutting capabilities are enabling the production of even finer and more complex mechanical parts.

6.2. Additive Manufacturing Integration: The integration of laser cutting with additive manufacturing techniques, such as 3D printing, is creating new possibilities for the production of intricate mechanical parts with improved structural integrity.

6.3. Industry 4.0 and Automation: The adoption of Industry 4.0 principles, including the use of IoT sensors and data analytics, is enhancing the efficiency and automation of laser cutting processes, leading to reduced downtime and waste.

6.4. Sustainability: Laser-cutting technology is becoming more environmentally friendly, with a focus on reducing energy consumption and material waste. Sustainable practices in laser cutting are gaining traction in response to growing environmental concerns.

-

Conclusion

Laser cutting has revolutionized the way mechanical parts are designed and produced. Its precision, versatility, and efficiency have made it an essential tool across various industries, from automotive to aerospace, electronics to healthcare. With ongoing advancements and innovations, laser cutting is set to play an even more significant role in shaping the future of manufacturing, driving the production of increasingly intricate and high-quality mechanical parts. As industries continue to demand precision and efficiency, laser-cutting technology is sure to remain at the forefront of mechanical part production.