How to Choose the Right Laser Cutting Service

November 13, 2023

The Future of Mechanical Parts Production with Laser Cutting

November 16, 2023How to Select the Right Laser Cutting Machine

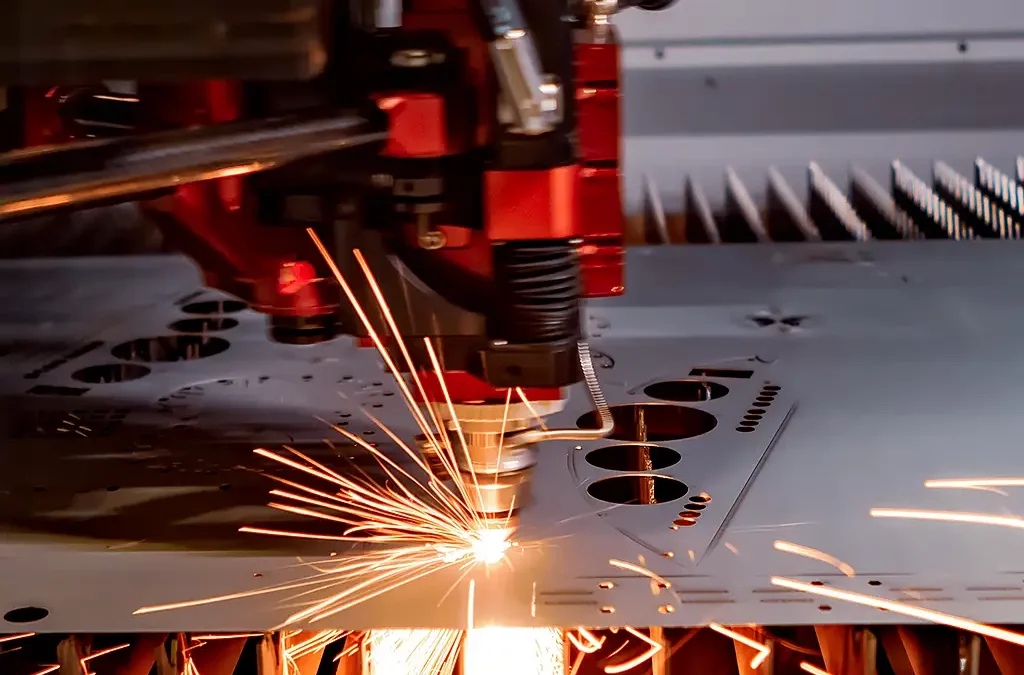

Laser-cutting machines have revolutionized the manufacturing industry, offering unparalleled precision and efficiency. Whether you’re a seasoned professional or just entering the world of laser cutting, choosing the right machine can be a daunting task. This article will guide you through the process, helping you make an informed decision for your specific needs.

Understanding Your Needs

Before delving into the technical aspects of laser-cutting machines, it’s crucial to understand your unique requirements. Here are some key factors to consider:

1. Material Compatibility:

- What materials will you be cutting? Metals, plastics, wood, or a combination of materials?

2. Cutting Thickness:

- Determine the maximum material thickness you’ll be working with.

3. Production Volume:

- Are you planning for small-scale or large-scale production? This will impact the machine’s speed and capacity.

4. Precision Requirements:

- Consider the level of precision you need for your projects. High precision may require more advanced laser systems.

5. Budget:

- What is your budget for the machine, including maintenance and operational costs?

6. Space Availability:

- Assess the available space for the laser cutting machine in your facility.

Types of Laser Cutting Machines

Laser-cutting machines come in different types, each suited for specific applications. The most common types are:

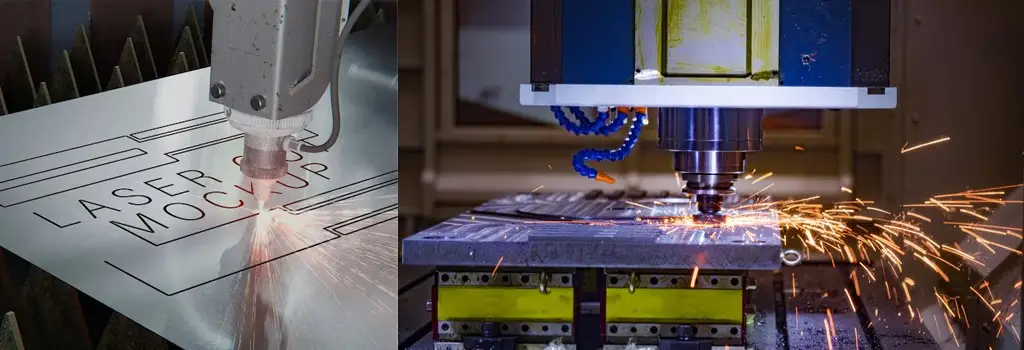

1. CO2 Laser Cutting Machines:

- Ideal for non-metal materials like wood, acrylic, and plastics.

2. Fiber Laser Cutting Machines:

- Suited for metal cutting, especially thin and medium-thickness metals.

3. Neodymium (Nd) YAG Laser Cutting Machines:

- Used for high-power cutting applications, including thick metals and ceramics.

4. Crystal Laser Cutting Machines:

- Suitable for fine and precise cuts on various materials.

Considerations for Laser Cutting Machines

Once you’ve assessed your needs and the types of machines available, there are several key factors to consider:

1. Power Output:

- The machine’s power output determines its cutting capabilities. Higher power machines can cut thicker materials and do so more quickly.

2. Cutting Speed:

- Different machines have varying cutting speeds. Assess if the speed aligns with your production requirements.

3. Laser Source:

- The choice between CO2 and fiber lasers depends on the materials you work with.

4. Quality of Cut:

- Evaluate the quality of cuts produced by different machines. Some may require less post-processing.

5. Maintenance and Operating Costs:

- Budget for ongoing maintenance and operational costs, including laser tube replacements.

6. Software and Control System:

- Consider the user-friendliness and compatibility of the machine’s software and control system with your existing workflow.

7. Safety Features:

- Prioritize machines with robust safety features to protect both operators and the machine.

Frequently Asked Questions (FAQs)

Q1: What safety precautions should I take when operating a laser-cutting machine?

A1: Safety is paramount when working with laser-cutting machines. Always wear protective eyewear, ensure proper ventilation, and follow all safety guidelines provided by the manufacturer.

Q2: Can I cut any material with a laser cutting machine?

A2: Laser-cutting machines are versatile, but the material must be compatible with the type of laser (CO2, fiber, etc.) used in the machine. Always check the material compatibility before cutting.

Q3: What maintenance is required for a laser cutting machine?

A3: Regular maintenance includes cleaning the optics, checking for gas leaks, and calibrating the laser. Be sure to follow the manufacturer’s maintenance schedule.

Q4: How can I extend the lifespan of my laser-cutting machine?

A4: Proper maintenance, using the machine within its specified limits, and regular cleaning are key to prolonging the machine’s lifespan.

Q5: Do I need specialized training to operate a laser cutting machine?

A5: Yes, specialized training is essential to operate a laser cutting machine safely and effectively. Many manufacturers offer training programs.

Selecting the right laser-cutting machine requires a deep understanding of your needs, the different machine types, and the factors that affect their performance. By taking the time to research and assess your requirements, you can make an informed decision that will positively impact your manufacturing processes.

Investing in the right laser-cutting machine is not just about buying a tool; it’s about enhancing your precision, efficiency, and overall product quality. With the right machine at your disposal, your mechanical parts production can reach new heights of excellence.