Meet our

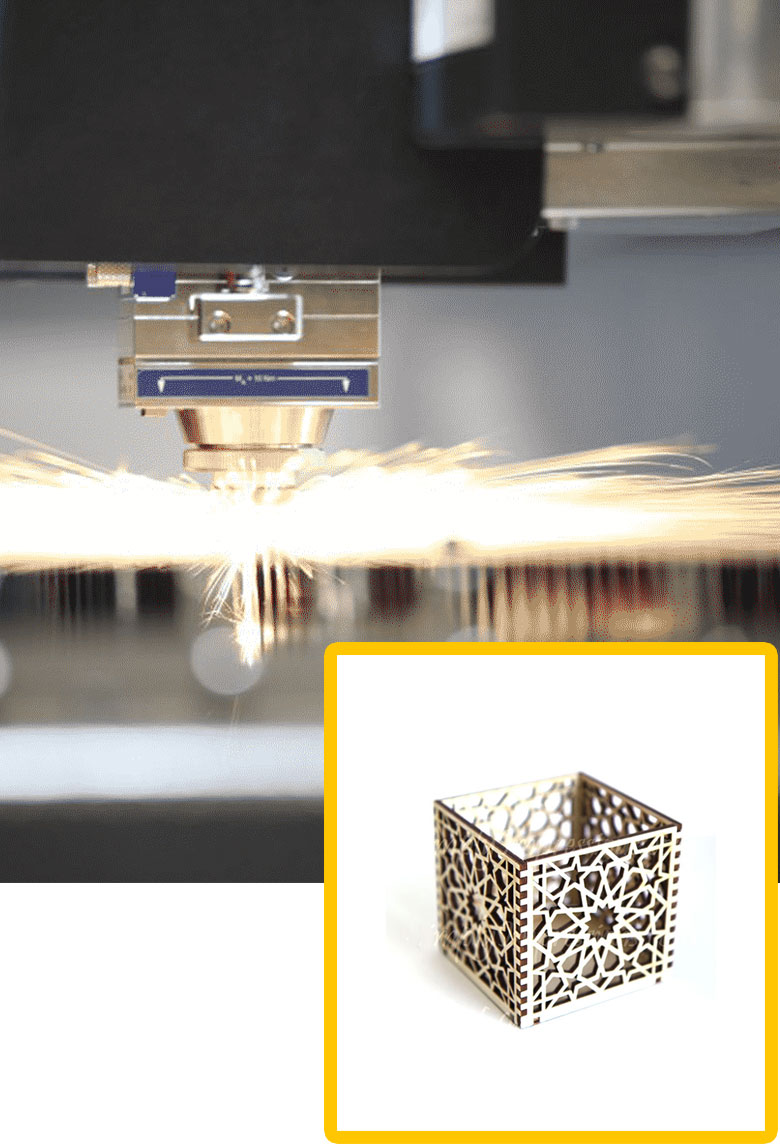

laser cutting

company

Al Madina Laser Cutting

High-Quality Laser cutting in Lahore

Al Madina laser cutting starts the art of laser cutting in Lahore with the aim of high-quality laser services for our clients in all over Pakistan.

Al-Madina Laser Cut specializes in both rapid short-run and production metal laser cutting and bending. We cut all metals, including steel, stainless steel, aluminum, copper, brass, and nickel. Air bending is offered in steel, stainless, and aluminum alloys at up to 1/4" thick, and copper and brass up to 1/8" Use our online quoting system to get instant pricing and order your parts online, or contact us for a quote on more specialized jobs.

Al-Madina's Best Services

Laser cutting Solution

Al madina laser cutting start the art of laser cutting in Lahore with the aim of high quality laser sercies for our clients in all over Pakistan.

Metal laser cutting services have revolutionized the manufacturing industry by providing precise, efficient, and cost-effective solutions for cutting and shaping metal materials. Laser cutting uses a high-powered laser beam to melt, burn, or vaporize the metal, resulting in a precise cut with a clean edge. Laser cutting is widely used in various industries, including automotive, aerospace, architecture, and construction. It has become a popular choice for metal fabricators who require precision and speed when cutting materials. There are many benefits to using laser cutting services for metal fabrication. Firstly, laser cutting allows for very high precision and accuracy, which makes it possible to create complex shapes and designs with minimal waste. Laser cutting is also fast, which means that large quantities of materials can be cut in a short period of time. This makes laser cutting a highly efficient method of metal fabrication. Another benefit of laser cutting is that it can be used on a wide range of materials, including steel, aluminum, copper, and other metals. It is also highly flexible, which means that it can be used to cut materials of different thicknesses and shapes. This makes it a highly versatile method of metal fabrication. The process of metal laser cutting involves a highly focused laser beam that is directed at the metal surface. The laser beam is controlled by a computer, which guides the beam along a pre-programmed path. The laser beam heats the metal to a high temperature, causing it to melt or vaporize, and resulting in a precise cut. Metal laser cutting services offer a variety of options to meet the needs of different customers. For instance, some services may offer custom laser cutting for specific shapes and designs, while others may offer bulk cutting for larger orders. Some services may also offer additional services, such as design and engineering support, finishing, and assembly. When choosing a metal laser cutting service, it is important to consider the service provider's experience, equipment, and customer service. The service provider should have a proven track record of delivering high-quality metal cutting services and should use state-of-the-art equipment to ensure precise and accurate cuts. Good customer service is also important, as it ensures that the customer's needs are met throughout the process.