Unlocking Precision and Versatility: Laser Cutting Services in Pakistan

January 6, 2024

Laser Cutting in Art and Design: Crafting with Precision

January 12, 2024The Marvels of Laser Cutting: An In-Depth Exploration

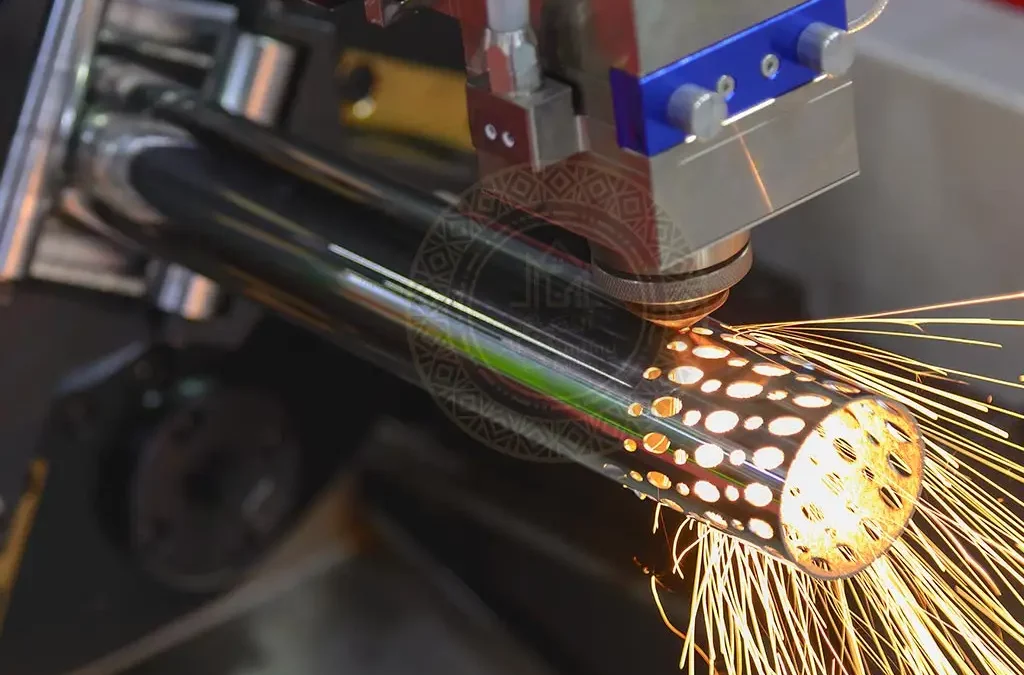

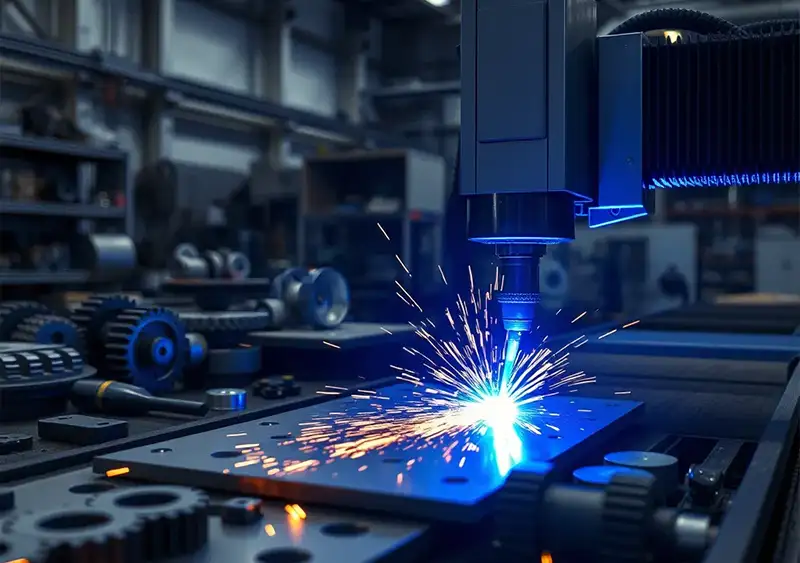

Laser cutting has revolutionized the world of precision cutting and engraving. In this comprehensive article, we’ll delve into the various aspects of laser cutting, its applications, and how it’s changing the game in manufacturing and design.

I. Understanding Laser Cutting:

- The Basics: A beginner’s guide to how laser cutting works and the science behind it.

- Materials for Laser Cutting: Explore the wide range of materials that can be cut with laser precision, from metals to fabrics.

- Applications: Discover the diverse applications of laser cutting, from industrial manufacturing to artistic creations.

II. Types of Laser Cutting Machines:

- CO2 vs. Fiber Lasers: A detailed comparison of CO2 and Fiber laser cutting machines, highlighting their strengths and weaknesses.

- 3D Laser Cutting: Explore the capabilities of 3D laser cutting and its applications in intricate designs.

III. Benefits of Laser Cutting Services:

- Precision and Accuracy: Discuss how laser cutting offers unparalleled precision, ensuring flawless cuts.

- Efficiency and Speed: Highlight the efficiency and speed advantages of laser cutting in comparison to traditional methods.

- Customization Possibilities: Explore the limitless customization options provided by laser cutting services.

IV. Industries Embracing Laser Cutting:

- Automotive: Examine how laser cutting has become a crucial component in the automotive industry for precise part manufacturing.

- Fashion and Textiles: Explore the creative applications of laser cutting in the fashion world for intricate fabric designs.

V. Future Trends in Laser Cutting:

- AI Integration: Discuss emerging trends in Artificial Intelligence integration with laser cutting technology.

- Advancements in Materials: Explore how developments in materials are expanding the possibilities of laser cutting.

Conclusion:

In conclusion, laser cutting is a transformative technology with widespread applications. Its precision, efficiency, and versatility make it an indispensable tool in various industries.

FAQs:

- How does laser cutting work?

- Laser cutting works by using a high-powered laser beam to precisely cut or engrave materials. The laser beam is controlled by a computer and directed onto the material’s surface, melting, burning, or vaporizing the material to create the desired shape or design.

- What materials can be cut with laser cutting?

- Laser cutting is versatile and can be used on various materials, including but not limited to metals (such as steel and aluminum), wood, acrylic, leather, fabric, and certain plastics. The ability to cut different materials depends on the type and power of the laser cutter.

- What are the advantages of laser cutting over traditional methods?

- Laser cutting offers several advantages over traditional methods, including:

- Precision: Laser cutting provides high precision and accuracy.

- Versatility: It can cut a wide range of materials.

- Speed: Laser cutting is often faster than traditional methods.

- Minimal Waste: The process minimizes material wastage.

- Complex Designs: It allows for intricate and detailed designs.

- Laser cutting offers several advantages over traditional methods, including:

- Can laser cutting be used for 3D designs?

- Yes, laser cutting can be used for 3D designs through a process known as 3D laser cutting or laser engraving. This technique allows the laser to cut or engrave materials in multiple layers, creating three-dimensional objects with intricate details.

- How fast is laser cutting compared to other cutting methods?

- Laser cutting is generally faster than many traditional cutting methods. The speed can vary depending on factors such as the material being cut, the thickness of the material, and the power of the laser cutter. In comparison to mechanical cutting methods, lasers often offer quicker and more efficient results.