Precision Unleashed: A Comprehensive Guide to Laser Cutting Technology

January 22, 2024

Mastering Precision with Linea Tube Laser Cutting

February 12, 2024In recent years, the laser cutting industry in Pakistan has experienced a remarkable surge, ushering in a new era of precision, efficiency, and versatility. This transformative technology has found its way into various sectors, from manufacturing to design, fueling innovation and boosting economic growth.

Unveiling the Power of Laser Cutting

Transformative Applications

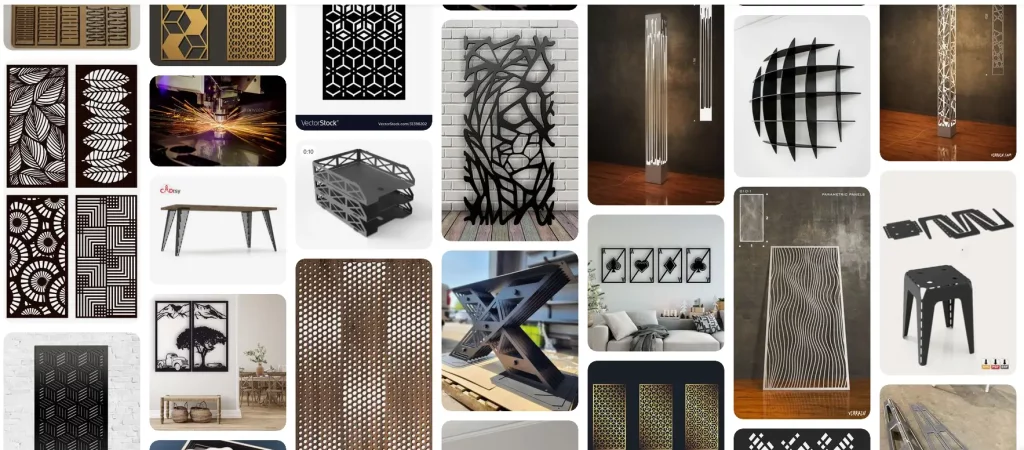

Laser cutting has proven to be a game-changer in Pakistan’s manufacturing landscape. The technology’s ability to cut and engrave materials with unparalleled precision has found applications in industries ranging from textiles and electronics to automotive and beyond. The versatility of laser cutting has made it a sought-after solution for businesses looking to streamline their production processes.

Precision in Design and Fabrication

One of the key drivers behind the industry’s growth is the unmatched precision offered by laser-cutting technology. Manufacturers and designers now can create intricate patterns, detailed prototypes, and customized components with razor-sharp accuracy. This precision not only enhances the quality of products but also opens doors to new possibilities in design and creativity.

The Rise of Laser Cutting Services

Accessibility for Small Businesses

What makes the growth of the laser cutting industry even more fascinating is its increasing accessibility for small businesses. With the advent of laser cutting services, businesses that might not afford the expensive machinery can now benefit from the technology on a contract basis. This democratization of laser cutting services has leveled the playing field for businesses of all sizes.

Customization and Personalization

Consumers today crave personalized products, and laser cutting has become a driving force behind this demand. From personalized gifts to bespoke home decor, businesses are leveraging laser cutting to offer unique and customized products. This trend has not only boosted the market but has also encouraged local entrepreneurs to explore niche markets with tailored offerings.

Industry Collaborations and Innovation

Collaboration with Educational Institutions

To sustain the momentum, the laser-cutting industry in Pakistan has actively collaborated with educational institutions. Workshops, training programs, and research partnerships have become commonplace, fostering a new generation of skilled professionals well-versed in laser cutting technology. This collaboration not only addresses the skills gap but also contributes to the continuous evolution of the industry.

Integration of AI and Automation

As part of its growth trajectory, the laser cutting industry in Pakistan is increasingly integrating artificial intelligence and automation. Smart laser cutting machines equipped with AI capabilities are enhancing efficiency, reducing waste, and optimizing production processes. This technological convergence is a testament to the industry’s commitment to staying at the forefront of innovation.

Overcoming Challenges and Paving the Future

Addressing Environmental Concerns

While the laser cutting industry brings numerous benefits, it is not without challenges. Environmental concerns, such as the emissions produced during the process, have been raised. However, industry players are actively investing in eco-friendly solutions and cleaner technologies to address these challenges and ensure sustainable growth.

Skills Development Initiatives

Another challenge faced by the industry is the need for skilled professionals who can operate and maintain laser-cutting machinery. To tackle this, various skills development initiatives, vocational training programs, and apprenticeships are being introduced to empower individuals with the expertise needed to contribute to the industry’s growth.

Laser Cutting Industry: The Ultimate Guide

Understanding Laser Cutting Technology

Laser cutting is a technology that uses a laser to cut or engrave materials. It works by directing the laser beam onto the material’s surface, which then melts, burns, or vaporizes, leaving a precise edge. This technology is highly versatile and capable of working with materials like wood, metal, plastic, fabric, and more.

Advantages of Laser Cutting

- Precision: Laser cutting offers unparalleled precision, making it ideal for intricate designs and fine details.

- Versatility: It can cut a wide range of materials, from delicate fabrics to thick metals.

- Efficiency: The process is fast and efficient, reducing production times and costs.

- Customization: Laser cutting allows for customization and personalization of products.

- Minimal Waste: The precision of laser cutting minimizes material wastage, contributing to sustainability.

Choosing the Right Laser Cutting Service

When selecting a laser cutting service in Pakistan, consider factors such as the provider’s reputation, the range of materials they can work with, turnaround times, and the quality of their finished products. Reading customer reviews and asking for samples can help you make an informed decision.

FAQs: Answering Your Queries

- Q: Is laser cutting safe for all materials? A: Laser cutting is generally safe for a wide range of materials, but it’s essential to consider the specific properties of each material. Certain materials may emit toxic fumes when cut, so proper ventilation is crucial.

- Q: Can laser cutting be used for large-scale manufacturing? A: Yes, laser cutting is scalable and can be used for both small-scale and large-scale manufacturing. Many industries in Pakistan are adopting laser cutting for its efficiency and precision in mass production.

- Q: How does laser cutting compare to traditional cutting methods? A: Laser cutting is often faster, more precise, and allows for intricate designs compared to traditional cutting methods. However, the choice depends on the specific requirements of the project.

- Q: Are there limitations to the thickness of materials that can be laser-cut? A: Yes, there are limitations. Laser cutting is most effective for materials of moderate thickness. Extremely thick materials may require specialized equipment.

- Q: Can laser cutting be used for 3D cutting? A: Laser cutting is primarily a 2D process. However, by employing advanced techniques like 3D laser cutting, some providers can achieve limited 3D cutting capabilities.

- Q: How can businesses integrate laser cutting into their operations? A: Businesses can integrate laser cutting by either investing in their machinery or outsourcing to laser cutting services based on their specific needs and production volumes.

- Q: Does laser cutting require significant maintenance? A: Regular maintenance is essential to ensure the optimal performance of laser cutting machines. Routine checks on optics, alignment, and cleanliness are recommended.

- Q: Are there safety precautions for operators working with laser cutting machines? A: Yes, operators should wear appropriate protective gear, and proper ventilation is crucial. Training on machine operation and safety protocols is essential for all personnel.

- Q: Can laser cutting services handle rush orders? A: Many laser cutting services offer expedited services for rush orders. It’s advisable to communicate your timelines with the service provider beforehand.

- Q: How is laser cutting contributing to sustainable practices in manufacturing? A: Laser cutting’s precision reduces material waste, and the industry is actively adopting eco-friendly technologies to address environmental concerns.

Conclusion

The laser cutting industry in Pakistan is not merely a technological evolution; it’s a beacon of innovation, collaboration, and growth. As businesses, educational institutions, and skilled professionals unite to harness the potential of laser cutting, Pakistan’s industrial landscape undergoes a profound transformation. This is not just the rise of an industry; it’s a testament to the nation’s commitment to progress, creativity, and a future illuminated by the power of lasers.