Laser Cutting Industry in Pakistan

November 30, 2023

Unlocking Precision and Versatility: Laser Cutting Services in Pakistan

January 6, 2024The Evolution of Laser Cutting Technology in Pakistan

The Evolution of Laser Cutting Technology in Pakistan:

Laser-cutting technology has revolutionized manufacturing and design processes across the globe, and Pakistan is no exception. From its humble beginnings to its widespread adoption across various industries, the story of laser cutting in Pakistan is a testament to the country’s growing technological prowess and its commitment to innovation.

Early Days and Adoption:

The initial introduction of laser cutting technology in Pakistan can be traced back to the late 1980s and early 1990s. During this period, the technology was primarily utilized in specialized research institutions and select high-end manufacturing facilities. However, its potential soon became apparent, and the demand for laser cutting services began to grow steadily.

Factors Contributing to Growth:

Several factors contributed to the rapid adoption of laser-cutting technology in Pakistan. One significant factor was the increasing demand for high-precision and efficient manufacturing processes, particularly within the textile, garment, and leather goods industries. Laser cutting offered unparalleled accuracy, speed, and flexibility compared to traditional cutting methods, leading to improved product quality, reduced production costs, and increased competitiveness in international markets.

Technological Advancements:

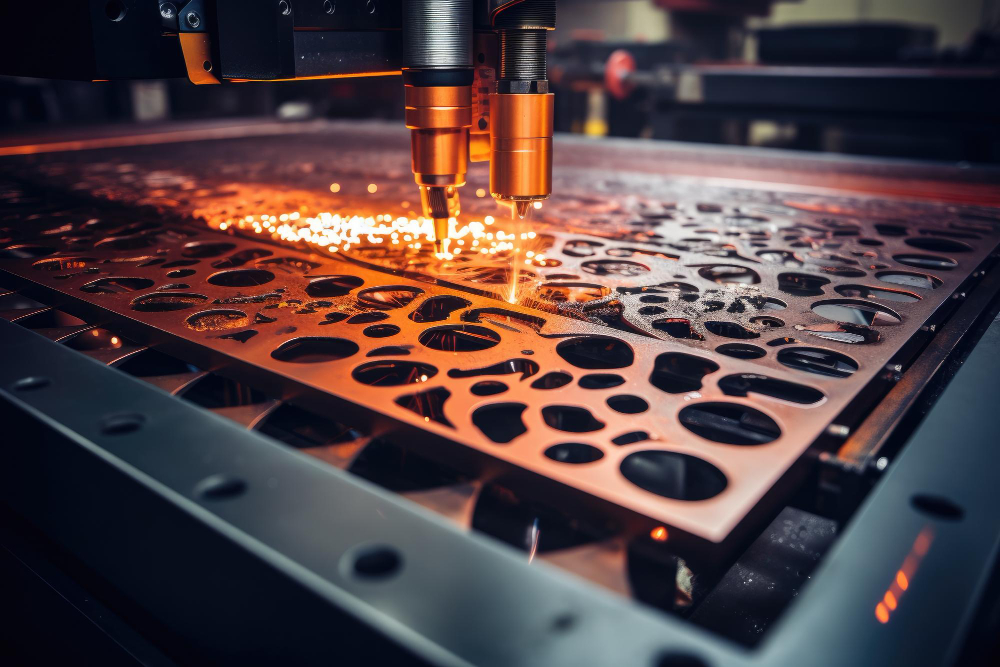

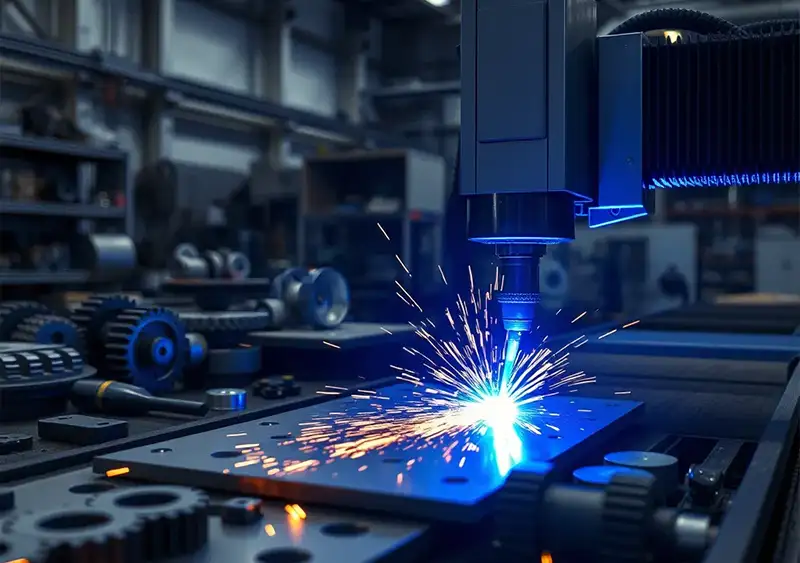

The continuous advancements in laser cutting technology have further fueled its growth in Pakistan. The introduction of fiber lasers, for example, has significantly improved cutting speeds, efficiency, and material compatibility compared to older CO2 laser systems. Additionally, the development of advanced software and control systems has made laser-cutting machines more user-friendly and accessible to a wider range of businesses.

Impact Across Industries:

Laser-cutting technology is now playing a crucial role in various industries across Pakistan, including:

- Textile and Garment: Precise cutting of intricate fabric designs, reduced fabric waste, and improved production efficiency.

- Jewelry Making: High-precision cutting of intricate jewelry designs, improved accuracy, and reduced manual labor.

- Metal Fabrication: Cutting of various metals, including steel, aluminum, and stainless steel, with high accuracy and minimal heat distortion.

- Woodworking: Precise cutting of intricate wood designs, customization options, and increased production speed.

- Medical and Dental: Precise cutting of medical devices, implants, and other delicate components.

Advantages and Disadvantages:

While laser cutting offers numerous advantages over traditional methods, it also has some limitations. The primary advantages include:

- High precision and accuracy: Ensures consistent results and minimizes waste.

- Increased speed and efficiency: Boosts productivity and reduces production time.

- Flexibility and versatility: Capable of cutting diverse materials and intricate designs.

- Reduced labor requirements: Automates cutting processes and minimizes human error.

However, it is crucial to consider the following disadvantages:

- High initial investment cost: Laser-cutting machines can be expensive to purchase and maintain.

- Limited material thickness: May not be suitable for cutting extremely thick materials.

- Safety concerns: Requires proper training and safety procedures to avoid potential hazards.

Future Trends:

The future of laser-cutting technology in Pakistan appears bright, with several exciting trends emerging:

- Increased adoption of fiber lasers: Offering faster cutting speeds, improved efficiency, and wider material compatibility.

- Integration with automation and robotics: Streamlining manufacturing processes and further enhancing productivity.

- Development of advanced software and control systems: Making laser cutting machines more user-friendly and accessible.

- Focus on sustainability and energy efficiency: Developing laser cutting systems with lower energy consumption and reduced environmental impact.

FAQs:

1. What are the most common applications of laser cutting in Pakistan?

The most common applications of laser cutting in Pakistan include textile and garment production, jewelry making, metal fabrication, woodworking, and medical device manufacturing.

2. Is laser cutting technology affordable for small businesses in Pakistan?

While the initial investment cost of laser-cutting machines can be high, several factors can make them affordable for small businesses. These factors include:

- Availability of financing options

- Increased productivity and efficiency leading to faster return on investment

- Reduced labor costs

- Ability to offer high-quality products and services at competitive prices

3. What are the safety considerations for using laser cutting technology?

Laser-cutting machines can pose potential hazards if not used properly. Therefore, proper training on the safe operation of these machines is crucial. Additionally, it is essential to wear appropriate protective gear, such as safety glasses and gloves, while operating the machines.