Precise and Efficient Laser Cutting for Mechanical Parts

April 20, 2024

The Advantages of Laser Cutting for Precision Mechanical Parts in Pakistan

May 11, 2024Precision Laser Cutting of Mechanical Parts in Pakistan

In today’s fast-paced manufacturing landscape, laser cutting technology has emerged as a game-changer, offering unparalleled accuracy, speed, and versatility. Pakistan’s burgeoning industrial sector has embraced this cutting-edge technology, particularly in the realm of mechanical parts production. Let’s delve into the world of laser cutting and explore its impact on the Pakistani mechanical parts industry.

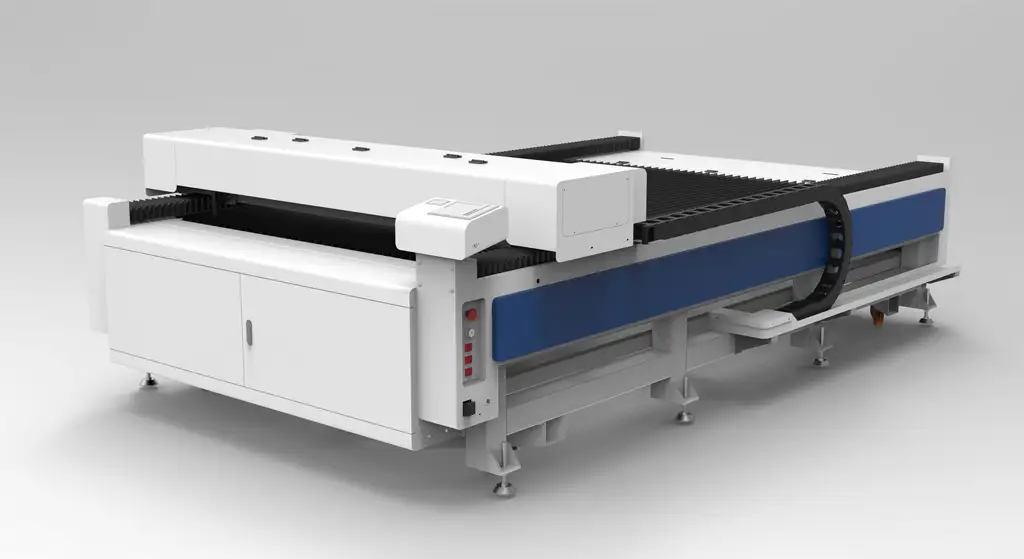

What is Laser Cutting?

Laser cutting is an advanced manufacturing process that utilizes a high-powered laser beam to precisely cut through various materials, including metals, plastics, and composites. The focused laser beam, typically generated by a carbon dioxide (CO2) or fiber laser, melts or vaporizes the material along the programmed path, resulting in clean, intricate cuts with exceptional precision.

Advantages of Laser Cutting for Mechanical Parts

- Precision: Laser cutting offers unmatched accuracy, allowing for the creation of even the most complex and intricate designs with tight tolerances.

- Speed: Compared to traditional cutting methods, laser cutting is significantly faster, resulting in increased production efficiency and reduced lead times.

- Versatility: Lasers can cut through a wide range of materials, including steel, aluminum, brass, copper, and even thick plates, making them versatile for various mechanical parts applications.

- No Mechanical Stress: Unlike conventional cutting methods, laser cutting does not exert mechanical stress on the workpiece, reducing the risk of deformation or warping.

- Minimal Finishing Required: The clean, burr-free edges produced by laser cutting often require minimal post-processing or finishing, saving time and resources.

Laser Cutting Applications in Pakistan’s Mechanical Parts Industry

Automotive Components

Pakistan’s automotive industry has witnessed significant growth, and laser cutting plays a crucial role in the production of various automotive components. From intricate chassis parts and body panels to suspension components and engine parts, laser cutting ensures precision, consistency, and efficiency in manufacturing.

Industrial Machinery Parts

The country’s industrial machinery sector relies on laser cutting for the production of high-quality components. Gears, sprockets, bearings, and other mechanical parts are precisely cut using laser technology, ensuring optimal performance and durability in demanding industrial environments.

Construction and Infrastructure Components

Laser cutting has revolutionized the construction and infrastructure sectors in Pakistan. Structural steel components, architectural elements, and decorative fixtures are produced with laser-cut precision, enabling innovative and visually stunning designs while maintaining structural integrity.

FAQs: Laser Cutting of Mechanical Parts in Pakistan

1. What materials can be laser-cut in Pakistan? Laser-cutting facilities in Pakistan can handle a wide range of materials, including mild steel, stainless steel, aluminum, brass, copper, and various other metals and alloys.

2. Can laser cutting handle thick materials? Yes, modern laser cutting machines can cut through thick materials, including heavy-duty plates and blocks, making them suitable for various industrial applications.

3. Is laser cutting cost-effective for small production runs? Absolutely! Laser cutting is highly efficient and cost-effective, even for small production runs or prototype development, as it eliminates the need for costly tooling and setup processes.

4. How does laser cutting compare to traditional cutting methods? Laser cutting offers superior precision, speed, and versatility compared to traditional cutting methods like plasma cutting, water jet cutting, or mechanical cutting. It also produces cleaner edges with minimal burrs or deformation.

5. Can laser cutting produce complex shapes and patterns? Yes, laser cutting excels in producing intricate shapes, patterns, and designs with exceptional accuracy, making it ideal for creating complex mechanical parts and components.

6. Is laser cutting suitable for mass production? Absolutely! Laser cutting is highly scalable and can be integrated into automated production lines, making it suitable for mass production of mechanical parts with consistent quality and efficiency.

7. How does laser cutting affect material properties? Laser cutting generally has minimal impact on the material properties, such as strength and hardness, as the heat-affected zone is minimal compared to other cutting methods.

8. Can laser cutting be used for engraving or marking? Yes, laser cutting machines can also be used for engraving, marking, or etching designs, labels, or logos onto mechanical parts, adding branding or identification elements.

9. What safety precautions are taken during laser cutting? Laser-cutting facilities in Pakistan follow strict safety protocols, including the use of protective equipment, enclosures, and ventilation systems to ensure the safety of operators and the surrounding environment.

10. How does laser cutting contribute to sustainability? Laser cutting is a relatively eco-friendly process as it generates minimal waste, reduces material consumption, and requires less energy compared to traditional cutting methods, contributing to sustainable manufacturing practices.