Space Dividers Reinvented: Laser Cutting Crafts Stunning, Functional Masterpieces

February 25, 2025

Gate Design Transformed: Laser Cutting Unlocks Breathtaking, Customized Looks

March 15, 2025Introduction

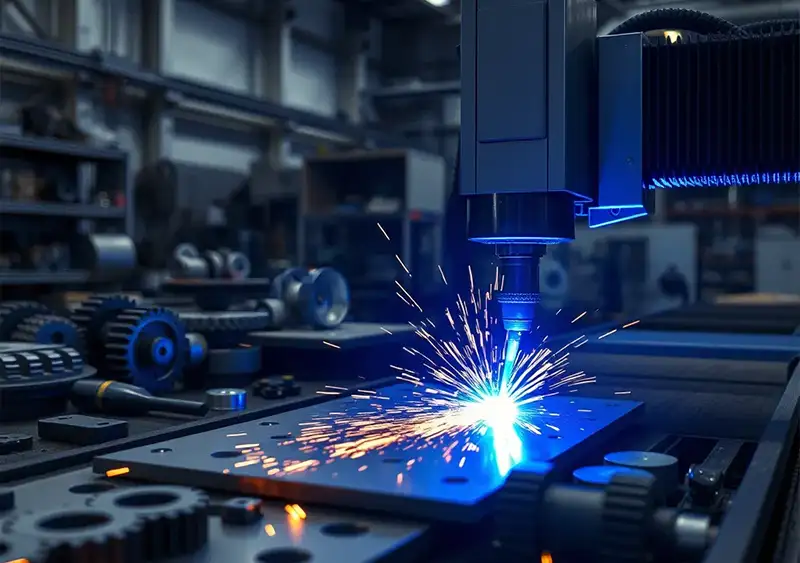

In the high-stakes world of manufacturing, precision and efficiency are the keys to success. Traditional cutting methods have long struggled to keep up with the ever-increasing demands of modern industrial production. But the game has been forever changed with the rise of laser cutting technology. In this article, we’ll unveil the closely guarded secrets of mechanical parts laser cutting, revealing how this cutting-edge technique can boost your precision and efficiency like never before.

The Laser Cutting Advantage

Unparalleled Precision

- Micron-Level Accuracy: Laser cutting offers an astounding level of precision, often accurate to within microns. This makes it the ideal solution for creating complex, intricate mechanical parts that traditional methods simply cannot match.

- Consistent Quality: The automated nature of laser cutting ensures flawless results, eliminating the risk of human error and variations in the final product.

Blazing Speed

- Rapid Production: Laser cutting machines operate at lightning-fast speeds, significantly reducing manufacturing time compared to conventional cutting methods.

- Streamlined Workflows: The quick setup and turnaround of laser cutting allow for faster prototyping, seamless production runs, and more agile response to market demands.

Unmatched Versatility

- Wide Material Compatibility: Laser cutting can handle a diverse range of materials, including steel, stainless steel, aluminum, brass, copper, and even plastics and woods, expanding the possibilities for mechanical part fabrication.

- Thickness Flexibility: Laser cutting systems can precisely cut through materials of varying thicknesses, offering unparalleled flexibility in part design and production.

Unlocking the Secrets of Laser Cutting for Mechanical Parts

Prototyping and Product Development

- Rapid Iteration: Laser cutting enables quick turnaround on prototypes, allowing designers and engineers to rapidly test and refine their designs.

- Cost-Effective Solutions: Prototyping with laser cutting is often more cost-effective than traditional methods, especially for small to medium-sized batches.

High-Volume Manufacturing

- Precision at Scale: Laser cutting is not just for prototyping; it can handle large-scale production runs with consistent quality and accuracy.

- Complex Geometries: Whether you need a small batch of custom parts or a high-volume production run, laser cutting can deliver intricate mechanical components with exceptional precision.

Specialized Applications

- Gear Components: Laser cutting can produce gear components with micron-level accuracy, ensuring smooth operation and minimal wear.

- Shafts and Axles: Laser-cut shafts and axles meet the stringent tolerances required for optimal machinery performance.

- Custom Brackets: Intricate bracket designs can be quickly and accurately fabricated using laser cutting technology.

Case Study: Laser Cutting in Automotive Manufacturing

Consider a scenario where an automotive manufacturer needs to produce a complex, mission-critical component for a new vehicle model. Traditional cutting methods would be time-consuming, potentially inaccurate, and expensive. By utilizing laser cutting, the manufacturer can:

- Reduce Production Time: From weeks to days, thanks to the lightning-fast speed of laser cutting machines.

- Increase Precision: Achieve cuts with minimal error, ensuring the parts fit together perfectly and function flawlessly.

- Enhance Quality: The consistent quality of laser-cut parts guarantees the final product meets the highest standards of performance and reliability.

How Al-Madina Laser Cutting Can Help

At Al-Madina Laser Cutting, we specialize in delivering exceptional laser cutting services for the mechanical parts industry. Our capabilities include:

- Precision Fabrication: Our advanced laser cutting systems ensure the highest level of accuracy, meeting the stringent requirements of mechanical part production.

- Rapid Turnaround: We offer industry-leading production times, making us the ideal partner for both prototyping and large-scale manufacturing.

- Personalized Support: Our dedicated team provides excellent customer service, ensuring your needs are met from design to delivery.

FAQs

What materials can be cut using laser cutting?

Laser cutting can handle a wide range of materials, including steel, stainless steel, aluminum, plastics, and woods.

How precise is laser cutting?

Laser cutting offers unparalleled precision, often accurate to within microns, making it the perfect solution for creating complex mechanical parts.

Can laser cutting be used for high-volume production?

Absolutely. Laser cutting is not just for prototyping; it can handle large-scale production runs with consistent quality and accuracy.

What is the typical turnaround time for laser cutting projects?

The turnaround time for laser cutting projects can be remarkably fast, often measured in days rather than weeks, depending on the complexity and volume of the order.

Is laser cutting cost-effective for small batches?

Yes, laser cutting can be more cost-effective for small to medium-sized batches compared to traditional cutting methods, thanks to the minimal setup time and rapid production capability.