Wall Cladding Meets Its Match: Laser Cutting Unlocks Endless Design Possibilities

November 5, 2024The Unexpected Way Laser Cutting is Revolutionizing Gate Design – You Have to See It!

December 5, 2024Introduction

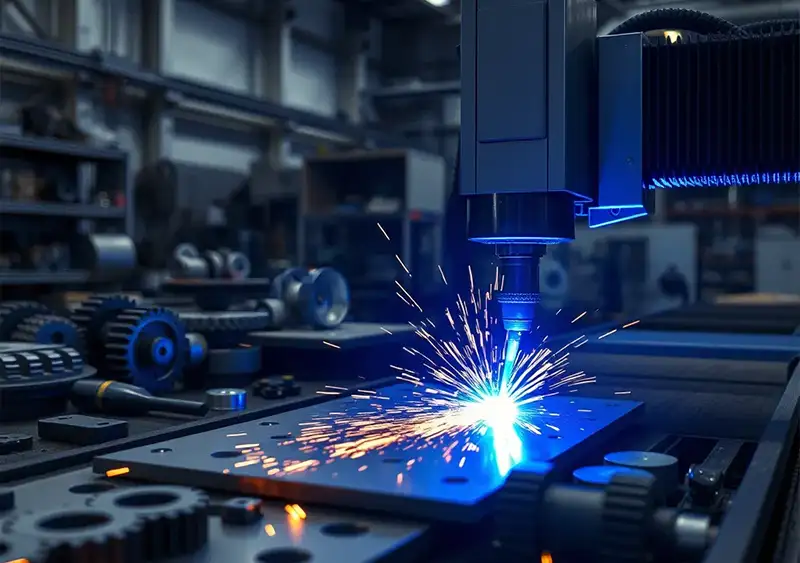

Laser cutting has revolutionized the way we fabricate mechanical parts, offering unparalleled precision, speed, and versatility. However, even with the most advanced technology, there are still ways to optimize the laser cutting process and achieve even more impressive results. In this article, we’ll share some mind-blowing mechanical parts laser cutting hacks that will take your fabrication game to the next level.

Hack #1: Optimize Your Design for Laser Cutting

- Simplify Complex Geometries: Break down intricate designs into simpler shapes to reduce cutting time and improve accuracy.

- Use Parametric Design: Utilize parametric design software to create flexible and adaptable designs that can be easily modified and optimized for laser cutting.

Hack #2: Choose the Right Material for the Job

- Material Selection: Select materials that are optimized for laser cutting, such as metals, plastics, and woods, to achieve the best results.

- Material Thickness: Choose the right material thickness to ensure optimal cutting performance and minimize waste.

Hack #3: Master the Art of Laser Cutting Settings

- Power and Speed: Experiment with different power and speed settings to find the optimal combination for your specific material and design.

- Frequency and Pulse Width: Adjust the frequency and pulse width to achieve the desired cutting effect and minimize heat damage.

Hack #4: Use Laser Cutting to Create Complex Joints and Assemblies

- Interlocking Parts: Design interlocking parts that can be easily assembled without the need for fasteners or adhesives.

- Kinematic Joints: Create complex kinematic joints that allow for smooth motion and precise control.

Hack #5: Post-Processing Techniques for Enhanced Finish and Functionality

- Deburring and Cleaning: Use deburring and cleaning techniques to remove excess material and achieve a smooth finish.

- Surface Treatment: Apply surface treatments, such as anodizing or powder coating, to enhance the appearance and durability of your mechanical parts.

Case Study: Optimizing Mechanical Parts for Laser Cutting

Imagine a company that specializes in producing complex mechanical parts for the aerospace industry. By applying the hacks mentioned above, they are able to:

- Reduce Production Time: By optimizing their designs for laser cutting, they reduce production time by 30%.

- Improve Accuracy: By using parametric design software, they improve accuracy and reduce errors by 25%.

- Enhance Material Efficiency: By selecting the right materials and optimizing material thickness, they reduce material waste by 20%.

The result is a significant improvement in production efficiency, accuracy, and material efficiency, allowing the company to stay competitive in the industry.

How Al-Madina Laser Cutting Can Help

At Al-Madina Laser Cutting, we understand the importance of optimizing the laser cutting process to achieve the best results. Our team of experts can help you:

- Optimize Your Design: Our design team can work with you to optimize your designs for laser cutting, ensuring the best possible results.

- Select the Right Material: Our material experts can help you choose the right material for your project, ensuring optimal cutting performance and minimizing waste.

- Master Laser Cutting Settings: Our technicians can help you master the art of laser cutting settings, ensuring the best possible results for your specific material and design.

FAQs

What are the benefits of optimizing my design for laser cutting?

Optimizing your design for laser cutting can reduce production time, improve accuracy, and enhance material efficiency.

How do I choose the right material for laser cutting?

Select materials that are optimized for laser cutting, such as metals, plastics, and woods, and choose the right material thickness to ensure optimal cutting performance.

What are the best laser cutting settings for my material and design?

Experiment with different power and speed settings to find the optimal combination for your specific material and design.

Can I use laser cutting to create complex joints and assemblies?

Yes, laser cutting can be used to create complex joints and assemblies, such as interlocking parts and kinematic joints.

What post-processing techniques can I use to enhance the finish and functionality of my mechanical parts?

Use deburring and cleaning techniques to remove excess material and achieve a smooth finish, and apply surface treatments, such as anodizing or powder coating, to enhance the appearance and durability of your mechanical parts.