Precision Laser Cutting of Mechanical Parts in Pakistan

May 8, 2024

Unlock Elegance: Exploring Laser-Cut Stair Railing Designs

May 15, 2024In the ever-evolving world of manufacturing, laser cutting technology has emerged as a game-changer, revolutionizing the way precision mechanical parts are produced. Pakistan’s industrial sector has embraced this cutting-edge technology, leveraging its capabilities to stay competitive in the global market. Let’s explore the advantages of laser cutting for precision mechanical parts in Pakistan.

What is Laser Cutting?

Laser cutting is an advanced manufacturing process that utilizes a high-powered laser beam to precisely cut through various materials, including metals, plastics, and composites. The focused laser beam, typically generated by a carbon dioxide (CO2) or fiber laser, melts or vaporizes the material along the programmed path, resulting in clean, intricate cuts with exceptional accuracy.

Key Advantages of Laser Cutting for Precision Mechanical Parts

1. Unparalleled Precision and Accuracy

- One of the most significant advantages of laser cutting is its ability to produce parts with unmatched precision and accuracy.

- The laser beam can cut through materials with tight tolerances, ensuring dimensional accuracy and repeatability.

- This level of precision is crucial in the production of mechanical parts, where even the slightest deviation can impact performance and functionality.

2. Intricate Designs and Complex Geometries

- Laser cutting excels in creating intricate designs and complex geometries that would be challenging or impossible to achieve with traditional cutting methods.

- The laser beam’s flexibility allows for the production of parts with intricate cutouts, curved shapes, and intricate patterns, enabling manufacturers to push the boundaries of design and innovation.

3. Wide Material Compatibility

- Laser-cutting technology can accommodate a wide range of materials, including metals, plastics, and composites.

- This versatility allows manufacturers in Pakistan to produce mechanical parts from various materials, such as steel, aluminum, stainless steel, titanium, and specialized alloys, ensuring optimal performance and durability for specific applications.

FAQ #1 What materials can be laser cut in Pakistan? Laser cutting facilities in Pakistan can handle a wide range of materials, including mild steel, stainless steel, aluminum, brass, copper, and various other metals and alloys, as well as certain plastics and composites.

FAQ #2 Can laser cutting handle thick materials? Yes, modern laser cutting machines can cut through thick materials, including heavy-duty plates and blocks, making them suitable for various industrial applications requiring precision mechanical parts.

Laser Cutting Applications in Pakistan’s Mechanical Parts Industry

The advantages of laser cutting technology have been embraced by various industries in Pakistan, including:

Automotive Components

- Pakistan’s growing automotive industry relies on laser cutting for the production of precision components, such as chassis parts, body panels, suspension components, and engine parts.

- The accuracy and repeatability offered by laser cutting ensure consistent quality and performance in these critical automotive applications.

Industrial Machinery Parts

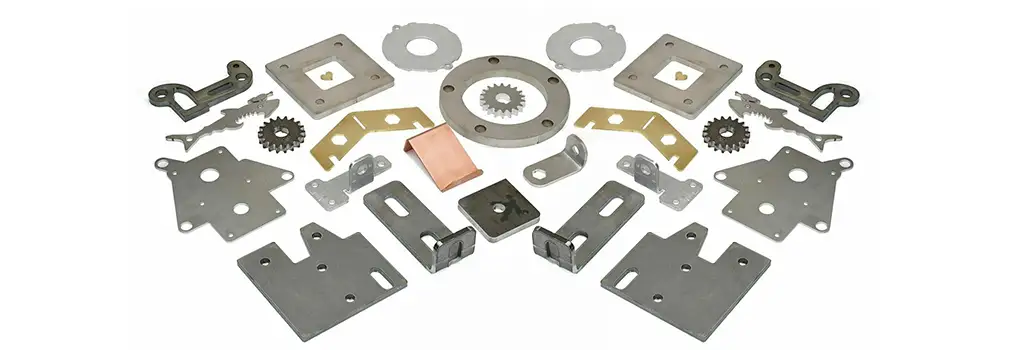

- The country’s industrial machinery sector benefits from laser cutting in the production of gears, sprockets, bearings, and other mechanical parts that require tight tolerances and durability.

- Laser cutting enables the creation of complex geometries and intricate designs, improving the performance and efficiency of industrial machinery.

Construction and Infrastructure Components

- Laser cutting has revolutionized the construction and infrastructure sectors in Pakistan.

- Structural steel components, architectural elements, and decorative fixtures are produced with laser-cut precision, enabling innovative and visually stunning designs while maintaining structural integrity.